Expert Solutions: Common Paint Spraying Problems Unveiled

Navigating through paint spraying challenges can be daunting, but with Ultrimax Ireland’s expert solutions, you can tackle them with confidence. Learn how to identify, understand, avoid, and fix common paint spraying problems to optimise efficiency and achieve superior results in your projects.

Our Total Paint Shop Support team answer an array of questions about paint spraying on a daily basis. Here are our most frequent issues and how to fix them:

Painter Mistakes Leading to Poor Finish

Neglecting Manufacturer’s Guidelines – Familiarise yourself with the manufacturer’s technical data sheet to ensure proper paint application.

Misjudging Paint Drying Times – One of the most popular problems that we hear about is paint drying times, there are many factors that can affect this. Drying paint in the winter can be particularly challenging, to overcome this, you may need to consider a heater and dehumidifier for the paint shop. We have several different Iwata infrared dryers available – contact us for more information.

Misjudging Paint Drying Times – One of the most popular problems that we hear about is paint drying times, there are many factors that can affect this. Drying paint in the winter can be particularly challenging, to overcome this, you may need to consider a heater and dehumidifier for the paint shop. We have several different Iwata infrared dryers available – contact us for more information.

Applying a thick layer of paint can also affect drying times, therefore it is important to thoroughly read the data sheets for guidance and purchase a thickness gauge.

Incorrect Spray Gun Set Up – Ensure proper gun setup and nozzle selection to prevent issues like overspray and uneven coating. Maintain optimal air pressure for consistent material application and prevent patchy finishes. In addition, regularly clean and maintain your spray gun and equipment to prevent build-up of debris from contaminating the finish. Click here to find out more about our range of paint spraying equipment.

Poor Adhesion Challenges

Peeling: Proper surface preparation and primer selection are crucial to ensure adhesion and prevent paint peeling. Ensure to thoroughly sand and clean the surface and make sure to research the correct primer for the desired result.

Wrinkling or Lifting (Urethanes and Enamels): This can happen when applying a new coat or in the drying phase. This can be a frustrating problem and can occur when the new coat attacks the old coat, ultimately causing it to lift. Ensure to read the manufacturers technical data sheets and to apply coats within the time specified.

Texture Issues

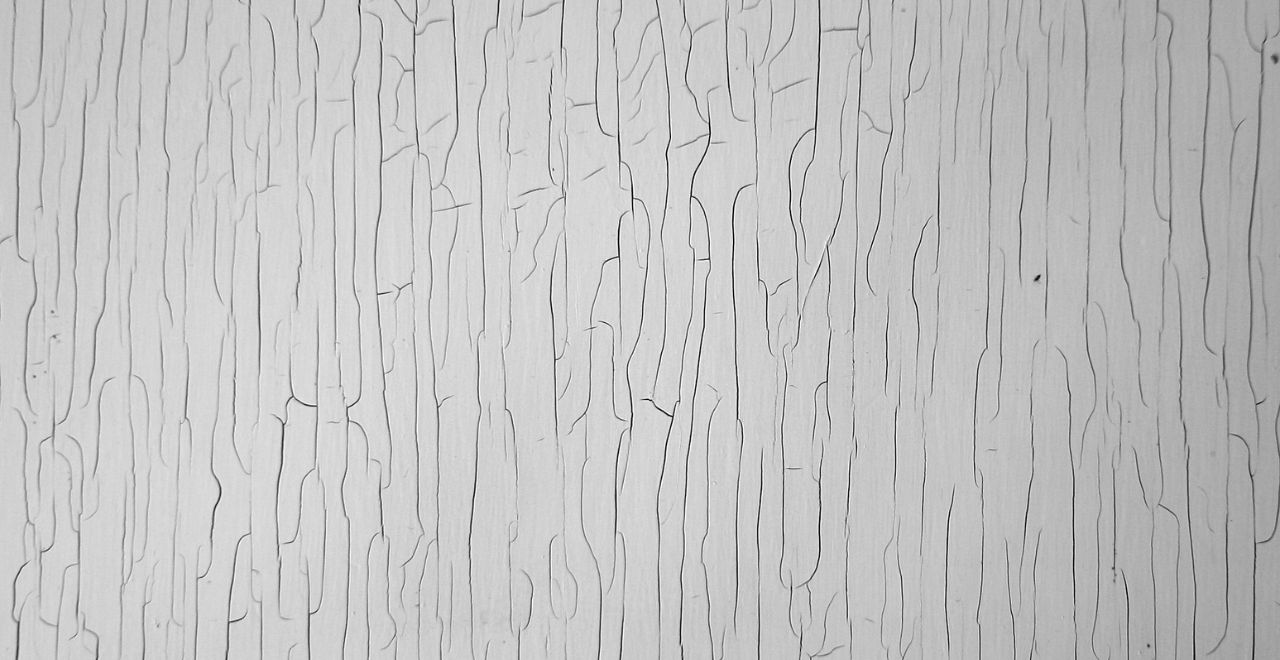

Cracking or spider webbing – This occurs for a variety of different reasons which include.

- The undercoat or topcoat applied is too thick.

- The surface that has been painted over has not been prepped correctly and is already cracked.

- Too much hardener has been used – causing an issue to the finish.

It is imperative that the surface is suitably prepped, sanded and cracks filled correctly. Also ensure that instructions are followed from the technical data sheets, as it may be that the incorrect paint systems are being used.

Grainy finish – This finish can occur when the spraying distance from the object is too far, as a result the paint particles atomise and dry before reaching their target. If this has occurred, sand back the object, test the correct distance and respray.

Fish eyes – Crater like dimples can happen during or after spraying, this is due to the substrate being contaminated with wax, grease or oil. To prevent this happening, ensure that the area is prepped correctly with a degreaser prior to priming or painting.

Dust and Grit – Particles in the paint can occur when spraying in a dirty or dusty environment:

- Avoid using old paint or primer.

- Clean the surface which is due to be painted and make sure to not paint in a dusty or dirty environment.

- Stir/strain paints prior to spraying.

Spray Painting Issues

Blushing – Misty and cloudy surface, this happens when the atmospheric conditions are incorrect, and the environment is humid. Evaporation of solvents in the paint lowers the surface temperature below the dew point, causing moisture to become trapped within the paint layer. To avoid this, we recommend using a high-quality reducer suitable for the conditions that you are spraying in.

Bleeding – Yellowish discoloration emerges on the topcoat above an application of glazing putty or filler. The cause of bleeding can happen for a number of reasons, but predominantly the hardener in the filler:

- The quantities of hardener in the filler are incorrect.

- Not mixing the filler thoroughly enough.

- Priming before the filler is fully cured.

Dulling of paint once the coating has dried – The main problem is due to the incorrect primer or topcoat being used. Refer to the technical data sheet to ensure that curing times are correct. In many cases if this has happened to your paint project, a compound and polish can restore the shine. If the dulling is severe, it may be the case that sanding off the topcoat is required and re spraying.

Conclusion:

In conclusion, many paint spraying issues can be prevented by adhering to several key steps and reading the technical data sheets. Following best practices is essential, alongside utilising high-quality products and honing your spraying techniques through practice. Additionally, conducting a test spray on a sample piece can help anticipate potential issues. Planning ahead and avoiding shortcuts are equally crucial, ultimately saving significant time and money.

Our Total Paint Shop Support team in Ireland are available to answer questions or queries about paint issues, whether you are in the joinery, plant & machinery or steel fabrication sector – we will also advise on best practises in the paint shop. Contact us for more information or to book your paint shop visit.